Ventilation of underground mines is a crucial criterion for their operational safety. An interruption to the ventilation is potentially life-threatening for the miners, includes an increased fire risk and failure of the production system. This means continuous residual current monitoring using RCMS is vital, as it detects any hazardous changes to the power supply immediately.

Drainage of underground mines is incredibly important. Any interruption to the drainage system increases the risks of shafts filling up with water and people being put in danger. From this perspective, continuous monitoring with ISOMETER®s or RCMS residual current monitoring systems is essential. They immediately recognise hazardous changes in the power supply.

Electric motors are generally employed for conveyor belts used in mining, which are driven by soft starters or frequency converters. However, these generate critical harmonic vibrations and DC currents which would not normally be present in the feeding AC system. With regular RCD or simple insulation monitors (e.g. 3 lamp method or 2 voltmeter process), this cannot be monitored with the requisite precision. There is a need for modern monitoring equipment which can recognise and report these problems quickly. Some standards even require a quick shutdown, which can be achieved using Bender insulation monitoring devices.

Mining vehicles are electrically powered. These cordless vehicles need monitoring of the earthing conductor in the cable (pilot wire monitoring). For this application, Bender offers a range of monitoring options, depending on the requirements for wire monitoring or fault current/earth conductor monitoring.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview - Residual Current Monitoring | Product Overviews | 4.2 MB | EN | 2026/02/1111.02.2026 | |

| Mining | Market Segment Brochures | 3.8 MB | EN | 2024/09/0404.09.2024 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2023/04/2121.04.2023 |

Products

Ground-fault/ground-continuity monitor

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

![[Translate to English:] LINETRAXX® CTUB100 Series](/fileadmin/_processed_/0/d/csm_CTUB10x-CTBCx_WEB_SI_d8b0d156d2.jpg)

AC/DC sensitive measuring current transformer (Type B)

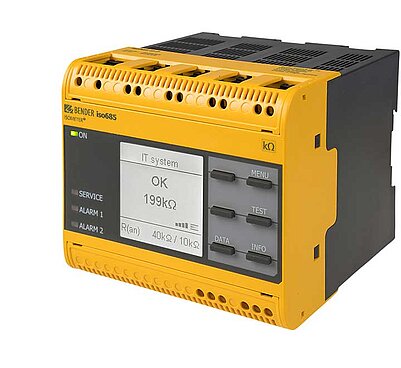

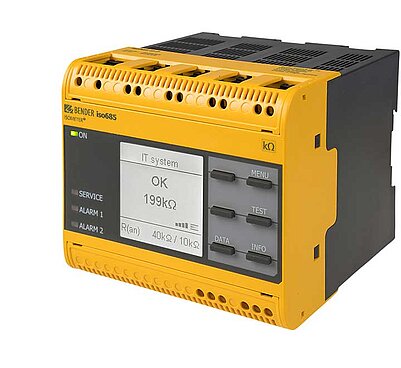

Insulation monitoring device for inverter applications and large industrial plants

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® iso685.../IR420-D64 series to AC 0...12 kV

Ground-fault/ground-continuity monitor

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

![[Translate to English:] LINETRAXX® CTUB100 Series](/fileadmin/_processed_/0/d/csm_CTUB10x-CTBCx_WEB_SI_d8b0d156d2.jpg)

AC/DC sensitive measuring current transformer (Type B)

Insulation monitoring device for inverter applications and large industrial plants

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® iso685.../IR420-D64 series to AC 0...12 kV

Maschinen für den Bergbau unter Tage - Anforderungen an bewegliche Maschinen für die Verwendung unter Tage - Sicherheit - Teil 1: Gummibereifte Gleislosfahrzeuge für den Bergbau unter Tage

Bergbaumaschinen unter Tage - Mobile Abbaumaschinen im Streb - Sicherheitsanforderungen für Walzenlader und Hobelanlagen

Electronic equipment for use in power installations

Errichten elektrischer Anlagen in Tagebauen, Steinbrüchen und ähnlichen Betrieben